Layers Laying Broilers: A Revolutionary Solution to the Hatchability Crisis

Earlier this year, Innovate Animal Ag released a report on the Hatchability Crisis in the US broiler industry. This research revealed that over the last decade, US broiler hatchability has declined by 6 percentage points from 85% to 79%. Despite the financial ramifications and the severity of the challenge, industry leaders have not yet zeroed in on underlying causes and effective solutions.

But while the industry debates whether the culprit of the current crisis is related to genetics tradeoffs, virulent bacteria, or breeder management practices, one startup, NextHen, a joint venture with the Volcani Institute, may have found a solution that doesn’t just provide incremental hatchability improvements, but fundamentally reimagines broiler breeding altogether.

NextHen's Layers Laying Broilers (LLB) technology represents a departure from conventional breeding. Rather than trying to squeeze better reproductive performance from birds genetically optimized for rapid growth, LLB breaks the genetic link between broilers and their parents entirely. The result? Layer hens with exceptional reproductive capacity laying eggs out of which fast-growth broiler chicks hatch.

We sat down with Dr. Yuval Cinnamon, the CSO of NextHen and Principle Investigator at the Volcani Institute, to learn more about how this is accomplished and its myriad production and welfare benefits. “Through the many decades of genetic selection,” Cinnamon told us, “two specialized breeds of chickens evolved. The performance of the resulting breeds is clearly excellent, but this comes with a price. The price is that broilers have very poor reproductive performance and the layers are excellent at laying but produce very little meat.”

Cinnamon and his team have addressed these costs using a clever genetic mechanism. Stated simply: they create layer hens who lay broiler chicks. They accomplish this by using genetic editing to create a sterile layer. They then isolate primordial germ cells from the fast-growth broilers, which “transfer the genetic material to the next generation,” according to Dr. Cinnamon. These germ cells are then transplanted in-ovo by a precision machine into the embryonic sterile layer. When the sterile layer grows up and starts laying hatching eggs, the hatching eggs contain a developing broiler-type embryo.

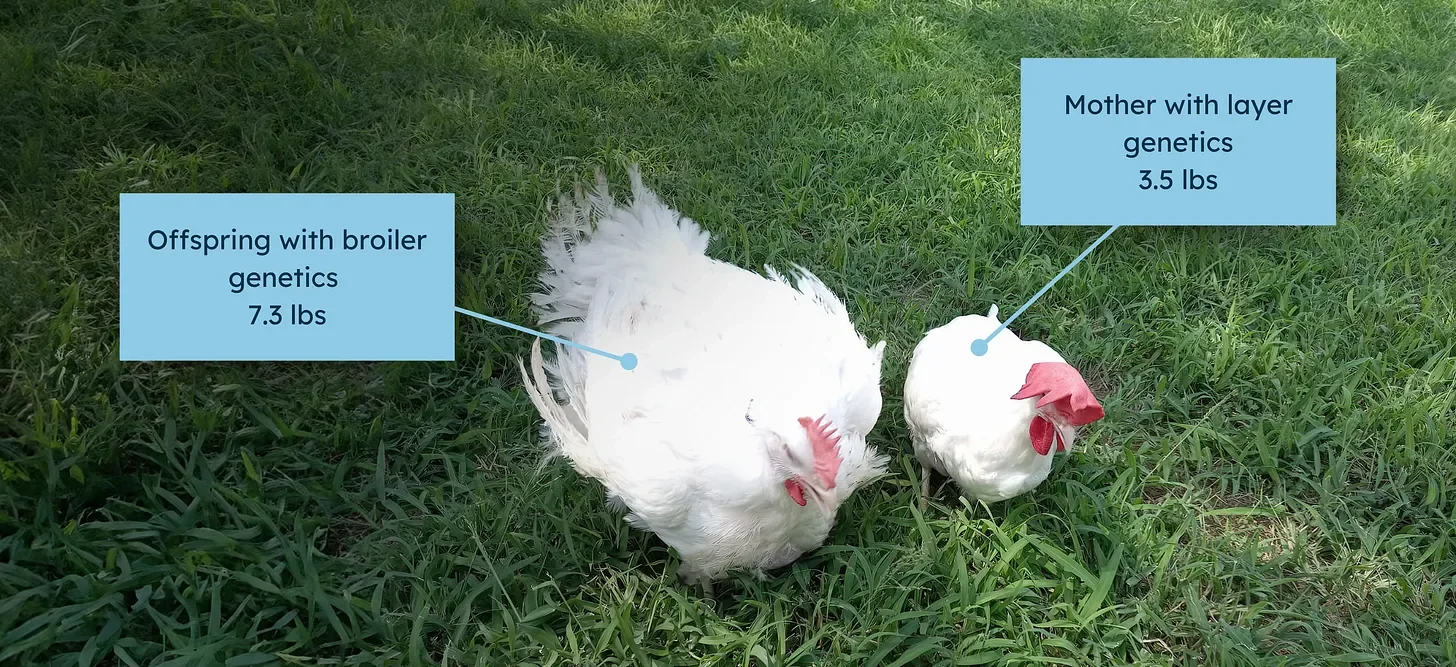

A proof of concept from the LLB project. On the right is a sterile surrogate hen, whose offspring is over twice as big as she is.

While layers can produce over 400 eggs during their productive life, broiler breeders tend to manage only around 140 fertile eggs. They have lower lay rates, decreased lay persistence, and worse baseline fertility levels. Not only that, broiler breeders require more feed to produce the same quantity of hatching eggs.

Broiler breeders also have to be heavily feed restricted. “If [the breeders] eat as the broilers they will grow so fast and become so heavy that they will not actually get to the age of sexual maturity,” Cinnamon says. One consequence of the feed restriction is that the breeders have elevated stress hormones. This leads to behavioral issues like increased fighting and pecking which can damage the birds and less voluntary mating which reduces fertility. These issues decrease fertility, increase labor costs, and lead to excess mortality.

In the US, most breeder farms also utilize individual rather than communal nest boxes. Typically, a breeder hen walks head first into an individual nest and turns around before laying an egg. If the hens have grown genetically larger over time while the individual nest boxes have stayed the same size, it may be difficult for hens to easily turn around, causing them to lay more eggs on the floor which have significantly worse hatchability rates. This is another important aspect of the Hatchability Crisis that the smaller LLB layers solve.

But the benefits don’t stop at the breeder flock level. Cinnamon explains that “the hatched broilers are exposed to these stress hormones and are likely to be stressed.” This can lead to worse animal welfare and production metrics at grow-out operations. “But if these broilers arise from a layer hen,” Cinnamon continues, they could potentially be “much more relaxed and without the stress hormones.”

One of the most remarkable aspects of this solution is that it is non-GMO. “We found a solution,” Cinnamon tells us, “which is by definition non-GMO. The broiler, which is the product that consumers eat, has zero genetic relationship with his [gene-edited] mother.” By keeping the end product completely free of genetic modification, LLB technology could achieve widespread adoption without some of the challenges that often affect uses of gene editing in animal agriculture.

The implications of LLB technology extend far beyond simply solving the immediate Hatchability Crisis. If implemented at scale, this approach could fundamentally restructure the economics of broiler production. With layers producing 2.5-3 times more eggs than current broiler breeders, the industry could dramatically reduce its breeder infrastructure needs—potentially halving the number of breeders and breeder-facilities needed. This translates to billions in savings from reduced feed costs, less capital and operational expenses, and lower disease vulnerability.

As global demand for chicken continues to grow and sustainability pressures intensify, technologies like LLB that simultaneously improve welfare, economics, and productivity will be essential.

NextHen is currently looking for commercial genetics partners to help scale up their technology. If you’re interested in learning more about NextHen and the LLB project, you can visit their website at https://www.nexthen.net/.